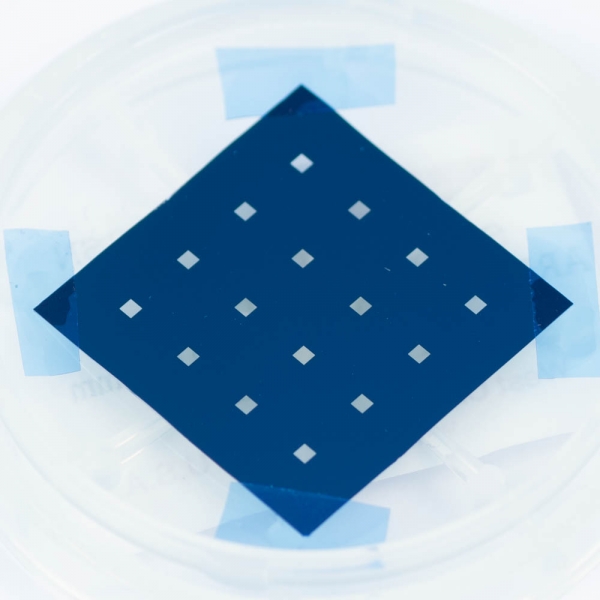

SPI Multi-Frame Array 5.0mm Square Frame 4x4 Array 100 nm Si3N4 1.0 mm Window 200 µm Silicon

| Availability | Contact for Availability |

|---|---|

| Item | 4139SN-AB |

Silicon Nitride Coated Membrane Window Arrays are an excellent choice for use with spin coating or further processing of the membrane windows with vacuum deposition techniques. These multi-frame arrays (MFA) offer the convenience of processing quantities of membranes at one time.

Specifications:

Outside Frame Size: 23.5 x 23.5 mm

Silicon wafer thickness: 200 µm

Individual grid frame size: 5.0 x 5.0 mm

Membrane Window Size: 1.0 x 1.0 mm

Silicon Nitride Thickness: 100 nm

Array Size: 4x4

Total Number of Membranes: 16

The Silicon Nitride membrane is always a "low stress" silicon nitride (as opposed to stoichiometric silicon nitride). For most users, the "low stress" membrane is the desired option.

Snapping Out the Frames:

These MFA are produced with scribe lines to allow breaking them out with ease. The scribe lines are on the underside of the array so they are not seen on the top side. To separate, first separate the outer frame from the array by pressing down gently with tweezers at the end of the scribe lines. A parting line start will form as the wafer bends and with a little more pressure, it will crack. At this point, the array should be turned over and the same thing done from the other side (being careful not to touch the top surface). Once one edge is off, take the other edges off in turn and then break out the columns of individual frames.

Spin Coating:

For spin coating, we recommend the Model KW-4A spin coater because of its ease of use and low price. Do not use vacuum to hold the MFA to the chuck since that vacuum will cause the membrane to bow outward and potentially lead to an uneven coating. Some researchers have developed special chucks that use clips rather than vacuum and resulting in another benefit of the MFA substrate.

Standard TEM Grid Multi-Frame Array:

MFA products are offered for use as TEM grids and can be found on the main Silicon Nitride Membrane Window Arrays page. These TEM grids have been etched so that no further prep is needed once they are snapped out of the frame.