Apiezon PFPE 501 Grease, CAS #69991-67-9 and CAS#9002-84-0

Apiezon PFPE 501 High Vacuum Grease

NOW! Certified by NSF as H1 food-grade lubricant and sealant!

Apiezon PFPE 501 is a chemically inert, high temperature and extreme pressure lubricant. With an upper operating temperature of 250°C and vapor pressure of 1.3 x 10-12 at 25°C, it is robust, versatile and can be used for sealing and lubricating under the most extreme operating conditions. This includes environments where aggressive chemicals and strong oxidizing agents are regularly used.

Apiezon PFPE 501 has proven to be an excellent sealant and lubricant in short path distillation, coating and semiconductor industries.

Apiezon PFPE 501 is also certified H1 food-grade by NSF International, which is the global independent body that certifies foodservice equipment and supplies for use to the industry. Having the H1 classification confirms that Apiezon PFPE 501 can be used safely in the food production chain where incidental food contact may occur. To achieve this level of accreditation with NSF, the content in the final product must not exceed 10ppm (parts per million).

Advantages of using PFPE 501:

Robust - Chemical inertness and oxidation stability make PFPE 501 ideal under the most extreme operating conditions.

Safe & Reliable - Non-toxic, nonflammable and maintains lubricity and thermal stability up to 250°C.

Extends Service Life – Branched PFPE structure and double-density provides film-forming and superior load-carrying capability.

Versatile - Used in a wide range of applications including bearings, valves, gears, threads, o-rings, and seals.

Compatibility:

Apiezon PFPE 501 is compatible with all types of material including plastics, metals, ceramics, polymers, elastomers, ethers, alcohols and hydrocarbons. At elevated temperatures it is recommended to avoid contact with Lewis acid catalysts such as aluminum chloride, boron trifluoride, titanium, tetrachloride and newly exposed rubbing surfaces of aluminum, magnesium or titanium alloys.

PFPE 501 is compatible with all chemicals, corrosives and solvents except those with a perfluorinated base.

Cleaning:

Wipe off excess grease with a lint-free cloth. Residual grease can be removed using a perfluorinated solvent. For stringent cleanliness, a further stage using acetone is recommended.

| Typical Property | Apiezon PFPE 501 | |

|---|---|---|

| Main areas of application | High temperature lubricating vacuum grease inert |

|

| NLGI No. | 2 | |

| Penetration P60 | 280 | |

| Typical working temperature range | °C °F |

-15 to 250 5 to 482 |

| Vapour pressure @ 25°C / 77°F, Torr | <1.3 x 10-12 | |

| Relative density @ 25°C / 77°F | 2.003 | |

| 4 ball wear scar (mm) ASTM D2266 (40kg) | 0.94 | |

| Outgassing characteristics ASTM.E 595-90 | TML CVCM |

<1% <0.1% |

| Evaporation 24hrs @ 100°C / 212°F | 0.02 | |

| Oil separation 24hrs @ 100°C / 212°F | 2.10 | |

| Low temperature torque, g/cm | 25°C / 77°F Starting 25°C / 77°F Running |

162.3 64.4 |

Ultra High Vacuum:

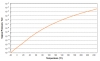

The extremely low vapor pressure characteristics of PFPE 501 (see Technical Data Sheet) ensure the grease can be used with confidence under ultra-high vacuum conditions.

Shelf life

The shelf life of Apiezon PFPE 501 is ten years from the date of manufacture, providing the product is in the original unopened packaging and has been stored at ambient (10 to 30°C) temperature.