ULTILE Precision Glass Cutters

| Size | 100mm |

|---|---|

| Item | 07730-AB |

| Availability | In Stock |

| Size | 200mm |

|---|---|

| Item | 07731-AB |

| Availability | In Stock |

| Size | 300mm |

|---|---|

| Item | 07732-AB |

| Availability | In Stock |

| Size | 400mm |

|---|---|

| Item | 07733-AB |

| Availability | In Stock |

| Size | 500mm |

|---|---|

| Item | 07734-AB |

| Availability | In Stock |

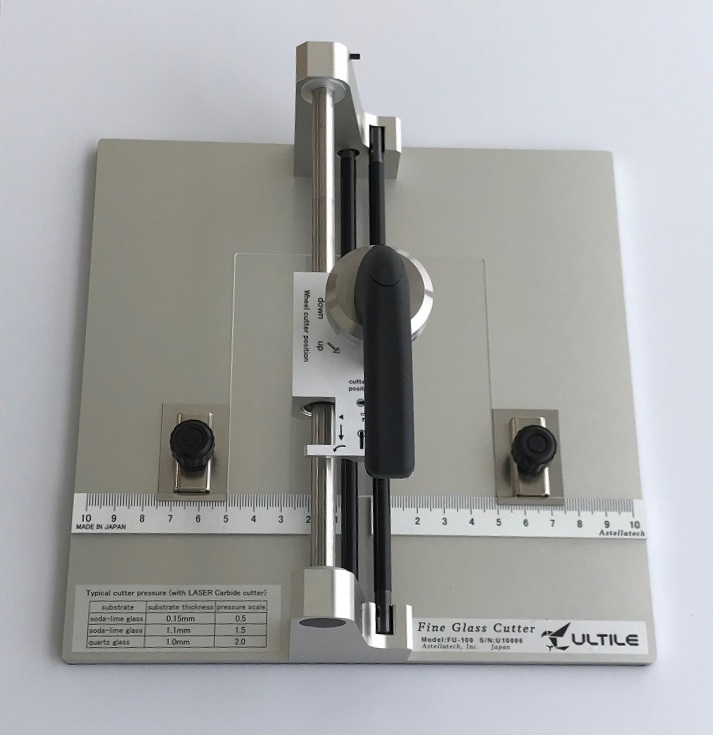

The ULTILE is the latest evolution of the popular SPI Supplies line of Precision Glass Cutters. These tools are designed to allow users to quickly and easily downsize large pieces of materials into smaller pieces, utilizing either a carbide or diamond cutting wheel. Technically they are not “cutters”, but rather they create a score mark in the material that allows the user to create a clean break along the scoreline. The ULTILE Cutters feature an adjustable pressure dial, allowing consistent scoring with every pass, with no pressure needed from the user. Each UTILE Precision Glass Cutter ships with (1) LASER Carbide wheel pre-installed.

Typical materials that can be cut with the ULTILE Precision Glass Cutter include:

• Glass (such as glass plates, slides, and coverslips)

• Quartz (such as quartz plates, slides, and coverslips)

• Silicon (such as large silicon wafers)

• Sapphire discs

• YSZ (yttrium stabilized zirconia)

Typically, pieces can be cut as small as 3cm x 3cm, but the minimum size is determined by the thickness of the material. Thinner materials, such as coverslips and silicon wafers can be cut to less than 5mm x 5mm in size with a little practice. This allows users to create their own custom size substrates, rather than having to special order them (usually at a special order price premium).

Operation is simple and repeatable:

1) Adjust the wheel height according to the thickness of the material being downsized.

2) Set the proper pressure from 1-50N

3) Align substrate material along the integrated scale to achieve the desired size

4) Use the optional magnetic holders to secure the material in place

5) Pull back on the scribing handle to create the score mark

6) Achieve a perfect cleave along the score mark either by hand or by using a pair of glass breaking pliers.

Four different carbide cutting wheels are available to handle standard materials from 0.15mm up to 3mm in thickness. There are also four different diamond cutting wheels available for use on harder materials (sapphire, YSZ, etc.) 0.15mm to 3.0mm in thickness.

Magnetic clamps are also available to securely hold substrates in place for cutting. The ULTILE Precision Glass Cutter is available in five sizes to accommodate a range of sample sizes: 100mm (4”), 200mm (8”), 300mm (12”), 400mm (16”), and 500mm (20”).

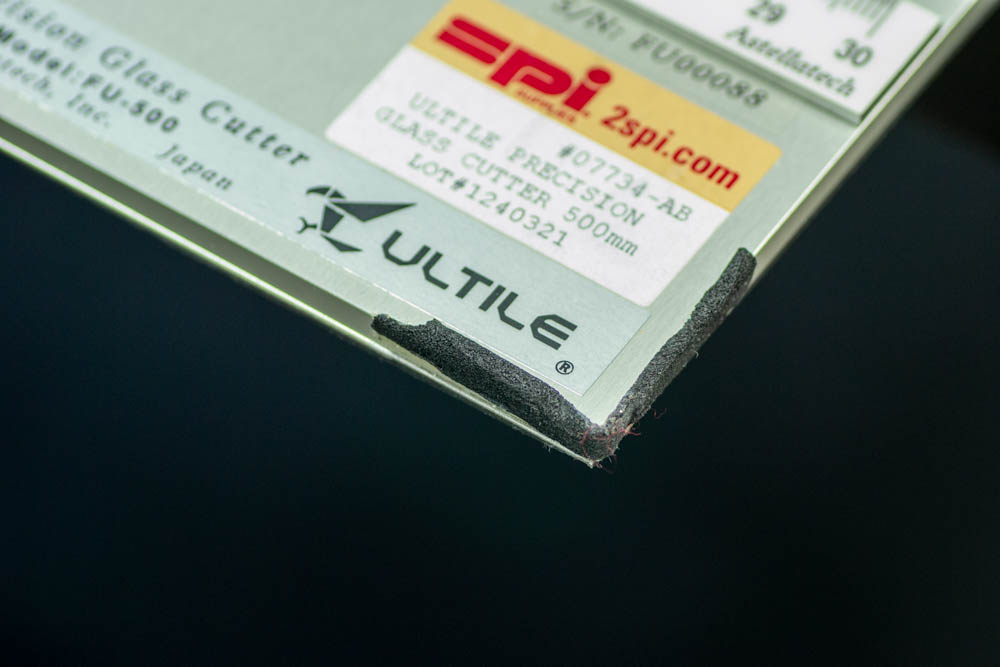

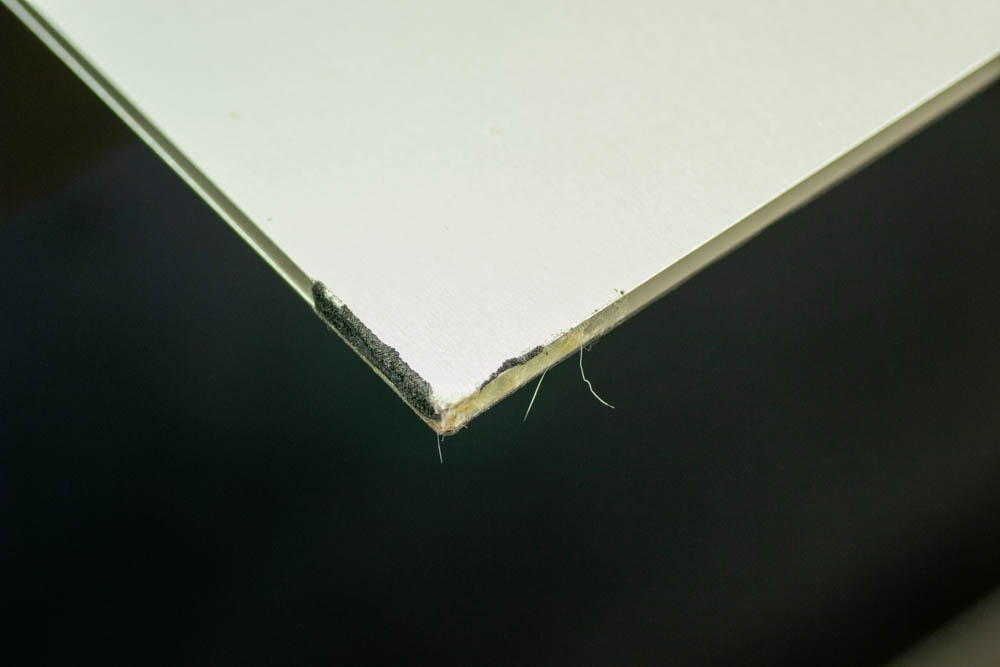

07734SD-AB Some slight cosmetic damages, but works perfectly. Here are the photos showing the areas of damage.