Graphene Oxide on Quantifoil R2/4 200 mesh Cu grids, pack of 10

| Availability | Contact for Availability |

|---|---|

| Item | 4510C-BA |

Graphene Oxide (GO) support films

Graphene Oxide offers distinct benefits as a thin support film for TEM. The background contrast due to a monolayer of GO is less than half that of even ultra-thin (3nm) amorphous carbon supports, opening up new applications and increased resolution for TEM.

Graphene has been heralded as the latest wonder material and its potential as thin support films for TEM along with GO has been known for some time. However, whilst Graphene grown by Chemical Vapor Deposition (CVD) offers the possibility of a continuous monolayer film, its production methods are technically complex and expensive for large scale manufacture of coated TEM grids. GO offers a cost effective alternative to Graphene for routine TEM applications. GO monolayers are typically <1nm and ideal for viewing nanoparticles by TEM when a continuous support is necessary. GO films are almost transparent under the electron beam and not easily visible under an optical microscope.

Structure and composition of Graphene Oxide (GO):

Graphene oxide is composed of a graphene-like sheet randomly decorated with oxygen functional groups such as epoxy and hydroxyl. Due to its graphene-like carbon backbone, even when only a monolayer thick, GO is strong enough to span the holes in a lacey carbon support or Quantifoil. GO is synthesized from graphite powder using a modified Hummers’ method. As produced, GO support films are hydrophilic. However, this can readily be changed by heating in air if a hydrophobic surface is required [1].

TEM applications for Graphene Oxide (GO):

Graphene oxide membranes are robust, conductive and almost electron transparent when used as support films for TEM. The low atomic number and thin-layer thickness results in significantly lower background contrast than conventional supports. This ultra-low contrast makes them particularly useful for imaging small nanoparticles or nanowires whose structure is not readily resolvable on conventional carbon supports [2]. Being inherently hydrophilic to which macromolecules readily attach, GO support films can also be used for imaging and analysis of polymeric, macromolecular and biological samples without the need for heavy metal staining [1]. GO support films are particularly useful for the preparation of unstained, vitrified biological macromolecules analyzed by Cryo–TEM [3] providing higher contrast and hence higher resolution for structural determination. The crystalline nature of GO gives a characteristic diffraction pattern which can be used as a convenient calibration for the analysis of other samples either by high resolution TEM or electron diffraction [1,2].

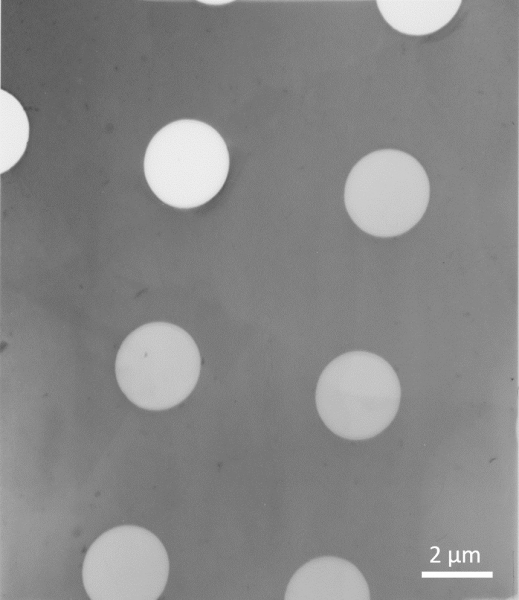

Graphene Oxide (GO) grid morphology:

Monolayer GO sheets need a sufficiently fine support so they can span the gaps. GO can be applied to various types of TEM support such as specially produced Lacey carbon films and Quantifoils. The latter is particularly useful for automated microscopy applications in structural biology. The GO sheets are distributed across the EM grids such that some holes in the lacey carbon support are uncovered, some covered by a single monolayer of GO, and some by two or more layers of GO. On average, roughly 50-75% of the lacey carbon holes are spanned by GO and of those roughly 50% are monolayer. GO support films are available from stock on Lacey carbon supports on 300 mesh copper grids. GO is also available on R2/4 Quantifoil on 200 mesh copper grids.

Assuring high quality Graphene Oxide (GO) support films:

The production of high quality GO support films requires regular batch checking using TEM, to ensure the correct coverage of monolayers. Monolayer thick GO is so thin as to be almost transparent under the electron beam and is often only apparent through small wrinkles or creases in the film. Overlapping sheets are also readily visible. The most effective way of determining the distribution of monolayer thick regions is from the diffraction pattern: a single layer has a hexagonal diffraction pattern similar to graphene, whilst multiple layers; that are usually in different orientations, give a multiple rotationally misaligned hexagonal pattern [1, 4]. It should be noted that sometimes this can also be caused by creases in a single sheet so some care must be taken with this interpretation. During manufacture each batch is checked for the correct thickness using TEM and diffraction. Before packing a further quality check is made where each grid is checked with an optical microscope before being placed in a specially selected white grid box.

References:

[1] A simple approach to characterizing block copolymer assemblies: graphene oxide supports for high contrast multi-technique imaging Joseph P. Patterson, Ana M. Sanchez, Nikos Petzetakis, Thomas P. Smart, Thomas H. Epps, III, Ian Portman, Neil R. Wilson and Rachel K. O’Reilly. Soft Matter 8, 3322 (2012). http://dx.doi.org/10.1039/C2SM07040E

[2] Graphene Oxide: Structural Analysis and Application as a Highly Transparent Support for Electron Microscopy. N.R. Wilson, P.A. Pandey, R. Beanland, R.J. Young, I.A. Kinloch, L. Gong, Z. Liu, K. Suenaga, J.P. Rourke, S.J. York, and J. Sloan, ACS Nano 3 (9), 2547 (2009). http://dx.doi.org/10.1021/nn900694t

[3] Graphene oxide: a substrate for optimizing preparations of frozen-hydrated samples. Pantelic RS, Meyer JC, Kaiser U, Baumeister W, Plitzko JM. (2010) J Struct Biol. Apr; 170 (1):152-6.

[4] Pandey, Priyanka A. (2012) Structure and applications of chemically modified graphene. PhD thesis, University of Warwick. http://webcat.warwick.ac.uk/record=b2654517~S1